cross-posted from: https://sh.itjust.works/post/50842014

When I moved into my home many years ago, there was this lock-box mounted to the water main on the side of the house. I figured it was one of those used by real-estate agents to store the house key for viewings, but months passed and it still remained there. No one from my buyer's agent's office had a clue what this was, and the seller of the house had already moved out-of-state.

Recently, I had some plumbing work done, and that also included replacing the main water valve for the house, allowing this lock box to come free from the plumbing. Now inspecting it up close, and looking up the model online, I realized that it has an alphabet wheel and uses a three-letter combination.

As it happens, Thanksgiving weekend was upon me, and since I was bored, I figured I'd try all the possible combinations. Just 17,576 possible combinations, how bad could it be?

The most immediate problem was that due to being out in the elements, the dial did not turn easily. It would move, but was rather rough. And since the knob is only ~1 cm diameter, this is an incredibly un-ergonomic endeavor. I had to stop after the first 100 tries, due to the finger exhaustion.

Knowing this would be untenable for the long-run, I decided to build my way out of this problem. Since a combo lock involves making rotations that almost go all the way around, I drew inspiration from rotary telephone dials, where one's finger starts with the intended number and then swivels the dial around.

But whereas a rotary telephone dial only needs 10 positions, I needed to fit 26 positions, one for each letter. I decided on each hole being 17 mm to comfortably fit any of my fingers, but that also dictated the overall diameter of the wheel. But that's good, since a larger diameter wheel means more leverage to overcome the rough lock movement. It also happens to be that this wheel has a diameter of 180 mm, which is just enough to fit in the 200 mm bed of my 3d printer.

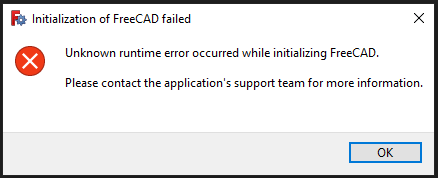

Using FreeCAD, I designed this wheel so that it fits around the splines of the lockbox dial, which held remarkably well. I had thought I would need Blu Tack or something to keep it together.

Using this wheel, I'm able to "dial" combinations much quicker using one hand, while holding the lockbox with my other hand to press the lever down to test the combination. This should be good.

(note: some parts of this story were altered to not give away identifying details)