Today I printed another one of this box. It's made of two half-shells that are printed with the outer face down on the bed.

The print went fine, but I'm not sure why, one of the half-shells had a whole area where the surface was really bad, with the criss-cross pattern all distorted, and even a single hole in the middle a good few layers deep. it was perfectly attached to the bed, and the print is otherwise perfect and functional. It just looks like crap.

Not wanting to spend another 2 hours reprinting it and wasting a working part, I figured I'd try chemically-polishing the heck out of it with acetone to improve its appearance a bit. Nothing to lose after all...

So lightly sanded the whole surface with 400-grit sandpaper and a block of wood to get rid of the most egregious defects, then I went to town on it with a clean microfiber cloth mounted on a straight edge and soaked with acetone.

I probably wiped the surface with the drenched microfiber cloth 15 times - up, down and sideways alternatively - until the surface looked okay. Not great, it was full of streaks, but better than the original misprinted surface.

I wasn't super-satisfied but I figured I couldn't make it any better. So I moved it aside to let it dry. As I grabbed it, I lightly touched it with my thumbnail, which left a a long, very visible shiny line. And I realized the PLA was so saturated with acetone that, although it looked dry, it has gone really soft.

So grabbed a few paper towels and started scrubbing the surface dry, nice and regular, again up and down and sideways: the plastic started becoming shinier and shiner. The PLA was so soft the paper tower was acting as a soft sandpaper!

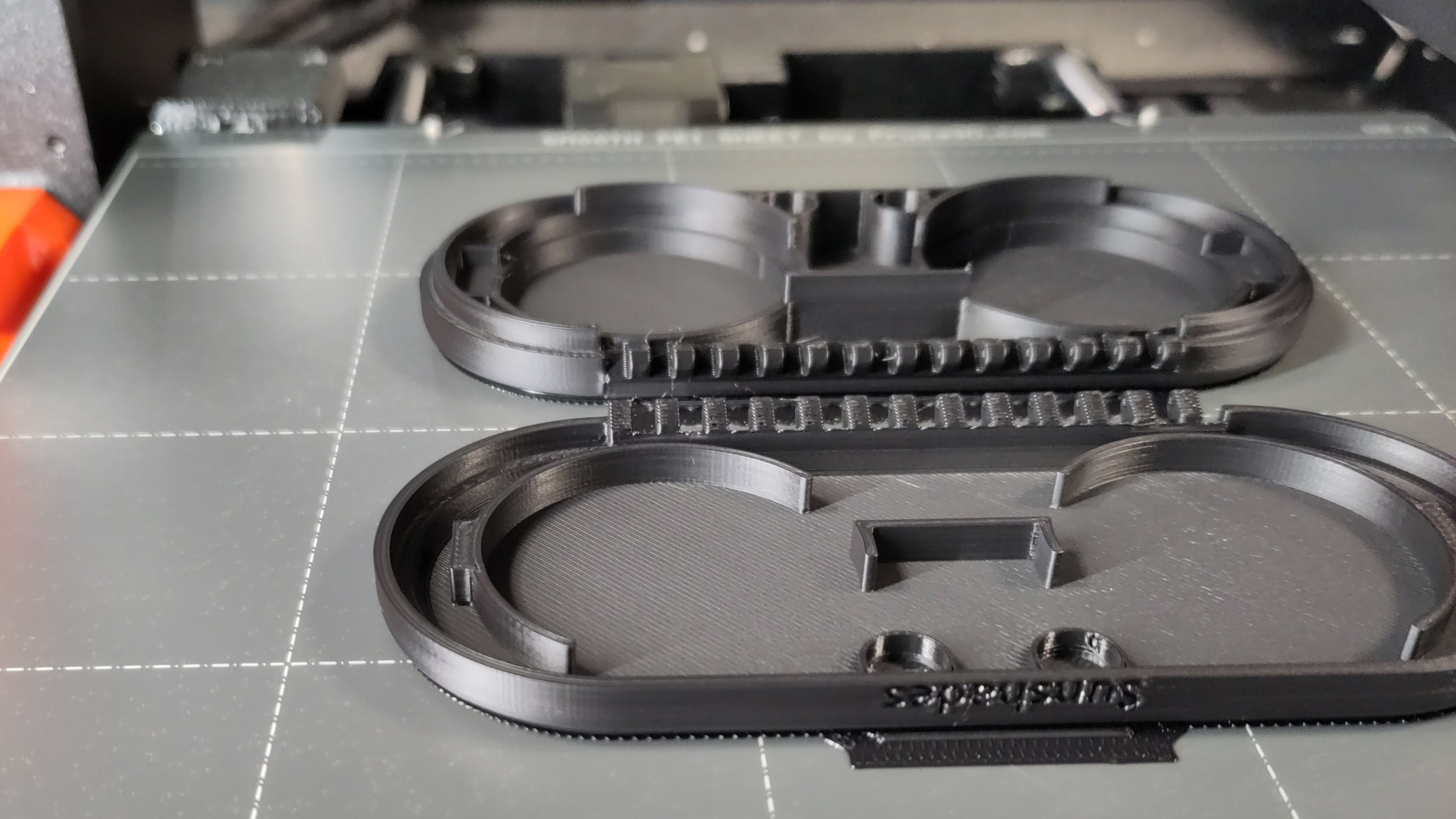

I kept at it until the PLA dried up and hardened again and nothing more was happening. And the result is the surface at the bottom of the photograph. It still has a hole in it - I just can't get that defect out - and you can still see some bad leftover criss-cross lines on the right that run too deep to remove entirely, but otherwise it is quite smooth.

Compared to the normal unpolished surface at the top (which came out of the printer good), it's not bad really. Also, I took the picture under harsh light to show as many surface defects as possible. But under ordinary lighting, the horizontal polishing lines aren't even visible. It's really smooth-looking.

I bet I could bring it out even shinier if I did another acetone soak and used a dry microfiber cloth for a final polish. But it's just a utility box and it'll get scratched up in my backback soon enough anyway, so there's no point.

I'm mentioning this interesting chemical polishing method - I mean soaking the part soft, letting it dry then polishing dry - because I've never done it and it looks really promising. You might want to give it a spin.